Disc Granulator

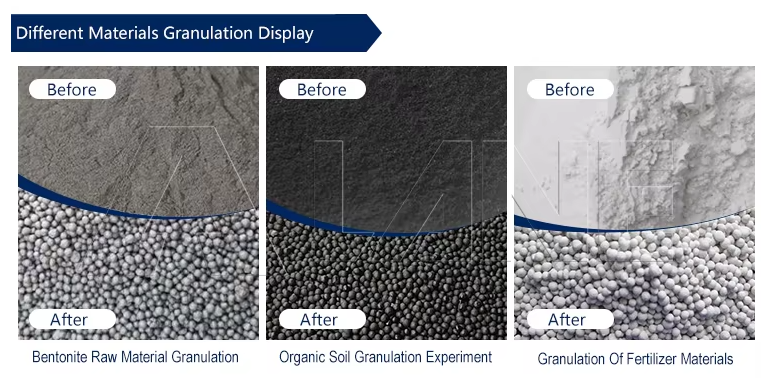

Disc granulator is a type of granulator that has the characteristics of uniform granulation, high granulation rate, and smooth operation. Widely used in the production of compound fertilizers and granulation of organic, inorganic compound fertilizers and elemental fertilizers, as well as in the processing of spherical particles of bio organic fertilizers, such as coal powder, cement, clinker, fertilizers and other materials.

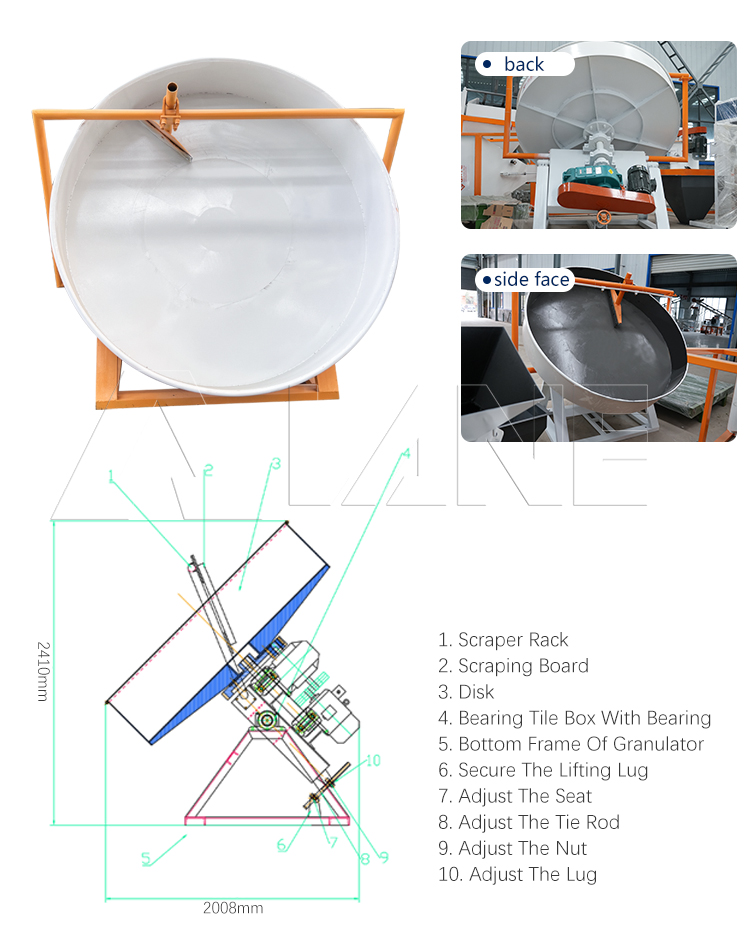

Composition structure

Main body: including frame, adjustment part, and granulation disc. The bottom of the disc is reinforced with multiple radiating steel plates, which are sturdy, durable, and never deform.

Transmission part: composed of a main reducer and an electric motor, driven by a flexible belt, ensuring smooth starting, reducing impact force, and improving equipment service life.

Base design: Thickened, weighted, and sturdy base design, without the need for anchor bolts to secure, ensuring smooth operation.

Working principle

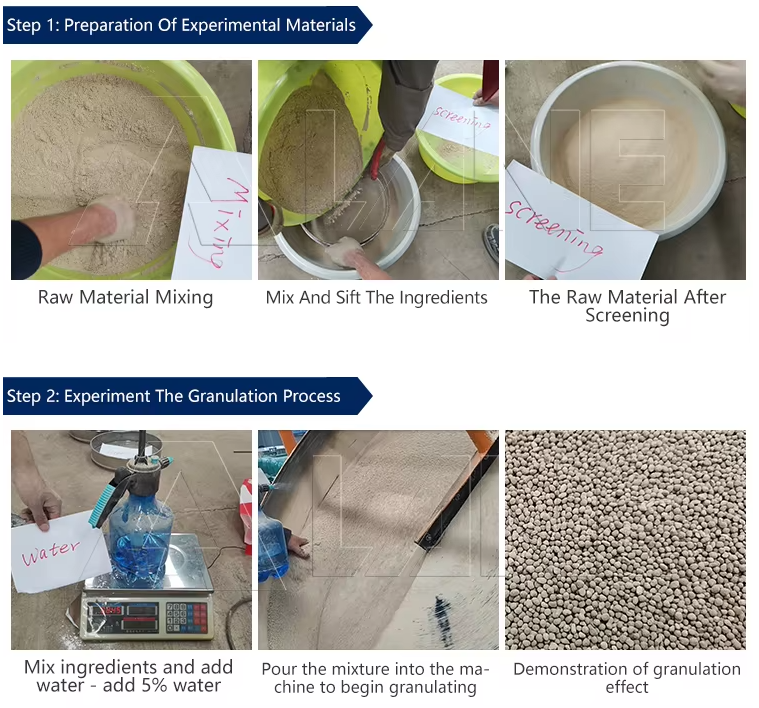

Raw material feeding: The raw materials that need to be granulated are fed into a disc through a feeding device, and can be in powder or granular form.

Ball formation process: The raw material is subjected to centrifugal force, frictional force, and gravity inside the disc, and moves along a parabolic path. Due to the adhesive and plastic properties of materials, they adhere to each other and gradually grow during movement. Then, as the tilted disc rotates, it is discharged from the edge of the disc.

Advantage

Efficient granulation rate: The granulation rate can reach over 93%, greatly improving work efficiency.

Smooth transmission: The reducer and motor are driven by flexible belts, which ensures smooth starting, reduces impact force, and extends equipment service life.

Flexible process layout: The structure is novel and reasonable, with reduced weight and height, suitable for the renovation of old factories.

In summary, the disc granulator not only has a reasonable structural design and advanced working principle, but also has the advantages of high efficiency and stability, making it an important granulation equipment in industries such as compound fertilizers. These characteristics make the disc granulator widely adaptable and efficient in practical applications, which can meet the material forming needs of different industries.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!