How to Construct an SSP Production Line in India: Cost, Process, Equipment & Expert Supplier

- 2026-01-08

With the rapid growth of agriculture and fertilizer demand, more investors and fertilizer manufacturers are planning to construct an SSP production line in India to meet the increasing need for single super phosphate fertilizers. SSP is widely used across Indian farmlands due to its high phosphorus content, affordability, and effectiveness in improving soil fertility.

However, successfully planning and executing a project to construct an SSP production line in India requires more than just purchasing equipment. It involves technical design, cost evaluation, process selection, equipment configuration, and choosing the right expert supplier. In this guide, we will walk you through every key aspect step by step, from feasibility to commissioning.

Why Construct an SSP Production Line in India Now?

India is one of the largest agricultural countries in the world, with a strong demand for phosphate fertilizers. Government policies continue to support fertilizer production, and SSP remains a preferred option for many farmers due to its simple formulation and stable market demand.

For investors and fertilizer plant owners, choosing to construct an SSP production line in India means:

- Lower raw material transportation cost

- Strong local market demand

- Favorable policy environment

- Faster return on investment compared to many other fertilizer projects

This is why more companies are shifting from importing fertilizers to building local production capacity.

Core Process to Construct an SSP Production Line in India

Before you construct an SSP production line in India, it is essential to understand the production process. A typical SSP production line includes the following steps:

1. Raw Material Preparation

The main raw material is rock phosphate, which is crushed and ground to a suitable fineness. Sulfuric acid is used as the reacting agent.

2. Acidulation Reaction

Rock phosphate reacts with sulfuric acid in the reactor. This is the heart of the process and determines product quality. Proper temperature and mixing control are critical when you construct an SSP production line in India.

3. Curing and Maturation

The material is discharged to a curing area or curing pit, where it matures for several days to complete the chemical reaction.

4. Crushing and Screening

After curing, the material is crushed and screened to obtain uniform particle size.

5. Packaging and Storage

Finally, the finished SSP fertilizer is packed and prepared for distribution.

Each of these steps must be precisely designed if you want to construct an SSP production line in India with stable quality and high output.

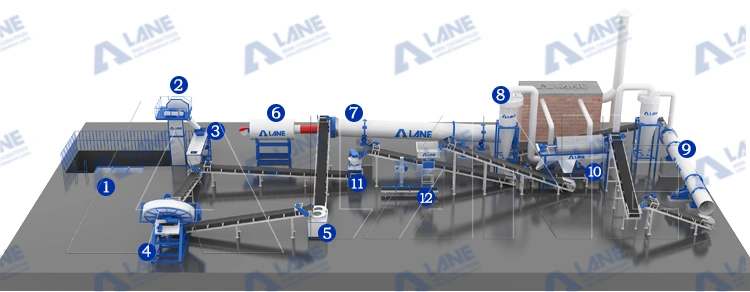

Key Equipment Needed to Construct an SSP Production Line in India

Choosing the right equipment is crucial. A standard configuration includes:

- Rock Phosphate Crusher – for size reduction

- Ball Mill or Raymond Mill – for fine grinding

- SSP Reactor / Acidulation Mixer – core reaction unit

- Curing System – curing pit or curing chamber

- Crusher & Screening Machine – for particle size control

- Conveying System – belt conveyors or screw conveyors

- Automatic Packing Machine – for final packaging

When planning to construct an SSP production line in India, equipment quality directly affects plant stability, maintenance cost, and product consistency.

Cost to Construct an SSP Production Line in India

The cost to Build an SSP production line in India varies depending on:

- Capacity (e.g., 10,000 TPY, 30,000 TPY, 50,000 TPY)

- Level of automation

- Equipment brand and material

- Local civil construction cost

- Utility system (water, power, dust collection)

As a general reference:

- Small-scale SSP line: lower investment, suitable for local markets

- Medium-scale SSP line: balanced investment and output

- Large-scale SSP line: higher investment but stronger market competitiveness

A professional supplier will always provide a customized budget plan when you plan to Build an SSP production line in India, instead of a generic price list.

Layout Design and Site Planning

Many investors underestimate the importance of layout. In reality, a reasonable plant layout can reduce material handling cost by 20–30%.

When you Build an SSP production line in India, the layout should consider:

- Raw material storage distance

- Reaction and curing area positioning

- Material flow direction

- Dust control and ventilation

- Future expansion possibility

A well-designed layout not only improves efficiency but also makes daily operation easier and safer.

Common Challenges When Constructing an SSP Production Line in India

Based on real project experience, these are the most common issues:

- Unstable reaction quality due to poor reactor design

- High maintenance cost from low-quality equipment

- Environmental compliance pressure without proper dust control

- Low output efficiency caused by unreasonable process layout

That is why choosing an experienced partner is critical when you Build an SSP production line in India.

Why Choose LANE to Construct an SSP Production Line in India

LANE Heavy Industry Machinery Technology Co., Ltd. is a professional manufacturer specializing in fertilizer production equipment and complete production line solutions. With years of engineering experience, LANE has helped clients in many countries successfully Build an SSP production line in India and other regions.

What LANE Offers:

- Turnkey Solutions – from design, manufacturing, installation to commissioning

- Customized Engineering Design – based on your capacity, site size, and budget

- High-Quality Equipment – durable, efficient, and easy to maintain

- On-site Installation Guidance – ensure smooth project execution

- After-Sales Support – technical support, spare parts supply, and training

When you choose LANE to Build an SSP production line in India, you are not just buying machines, you are partnering with a technical team that understands real production challenges.

How Long Does It Take to Construct an SSP Production Line in India?

Normally, the timeline includes:

- Design & engineering: 2–3 weeks

- Equipment manufacturing: 30–45 days

- Site preparation & civil work: parallel process

- Installation & commissioning: 10–20 days

In total, most projects to construct an SSP production line in India can be completed within 2–3 months, depending on scale and site readiness.

Environmental Protection and Safety Considerations

Environmental compliance is increasingly important in India. A professional SSP production line should include:

- Dust collection system

- Acid mist absorption system

- Wastewater treatment solution

- Noise reduction design

LANE integrates these systems when helping clients Build an SSP production line in India, ensuring both production efficiency and regulatory compliance.

FAQ – Construct an SSP Production Line in India

Q1: Is SSP still profitable in the Indian market?

Yes. SSP remains in strong demand due to its affordability and effectiveness. Many regional markets still rely heavily on SSP fertilizers, making it a stable investment.

Q2: What capacity is best for beginners?

For new investors planning to Build an SSP production line in India, a 10,000–30,000 TPY line is often recommended for lower risk and faster ROI.

Q3: Can the line be upgraded later?

Yes. A well-designed production line can be expanded in the future. LANE always considers future scalability when helping clients construct an SSP production line in India.

Q4: Do I need special technical staff?

Basic training is enough. LANE provides operation training and technical guidance during commissioning.

Q5: How do I get a customized plan?

You can contact LANE with your site size, target capacity, and budget. Our engineers will prepare a tailored solution for your project.

Final Thoughts

To construct an SSP production line in India is not just an equipment purchase decision—it is a complete project investment. From process design and equipment selection to layout planning and environmental compliance, every step affects your final profitability.

Working with an experienced supplier like LANE ensures that your project is built on proven technology, reliable equipment, and professional engineering support. If you are planning to Build an SSP production line in India, now is the right time to take action and secure your position in the growing fertilizer market.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520