How to Build an SSP Fertilizer Plant: A Complete Guide

- 2025-08-14

For companies and investors entering the fertilizer industry, understanding how to build an SSP fertilizer plant is essential. Single Super Phosphate (SSP) fertilizer remains one of the most widely used phosphorus fertilizers worldwide due to its cost-effectiveness and soil benefits. In this guide, we will walk you through the key steps to build an SSP fertilizer plant, highlight the critical equipment involved, and show how LANE Heavy Industry’s advanced SSP solutions can help you achieve efficient, high-quality production.

Step 1: Define Production Capacity and Goals

The first step to build an SSP fertilizer plant is to define the target production capacity, which directly influences plant design, equipment selection, and process efficiency. Typical capacities range from 50,000 tons/year for small regional operations to over 200,000 tons/year for large-scale export. Precise capacity planning allows engineers to determine crusher throughput (t/h), mixer volume (m³), granulator rotation speed (rpm), and curing area (m²). LANE Heavy Industry offers modular SSP production lines that can be scaled easily, allowing clients to expand capacity by adding parallel granulators or curing chambers without major redesign, ensuring long-term ROI and flexibility.

Step 2: Select and Prepare Raw Materials

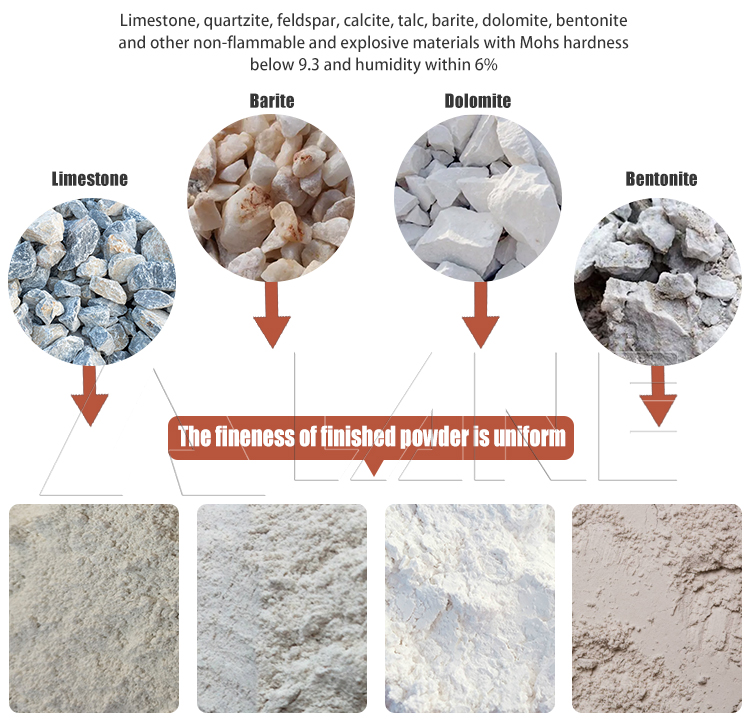

When you build an SSP fertilizer plant, raw material quality is critical. The primary ingredients are:

-

Phosphate rock with P₂O₅ content ≥ 28% for optimal phosphorus yield. Rocks with high Fe₂O₃ or SiO₂ may slow acidulation; LANE’s inline XRF analyzers provide real-time impurity detection to maintain reaction efficiency.

-

Industrial-grade sulfuric acid (98%), with precise dosing controlled by mass flow meters to achieve complete acidulation.

Additional preparation includes:

-

Crushing rock to 75–150 μm to improve surface area for reaction.

-

Moisture control at 1–2%, measured via near-infrared (NIR) sensors, ensuring smooth mixing and preventing dust or sticking.

-

Blending raw materials with uniform homogeneity using paddle or ribbon mixers, maintaining a mixing coefficient of variation <5%, which is critical for consistent granulation.

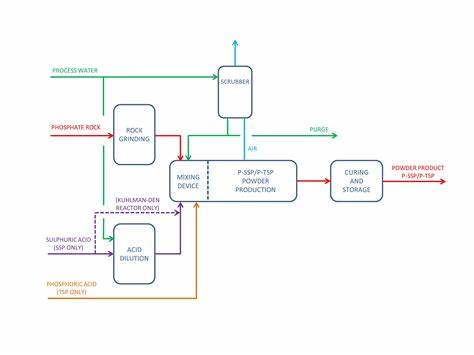

Step 3: Design the Production Process

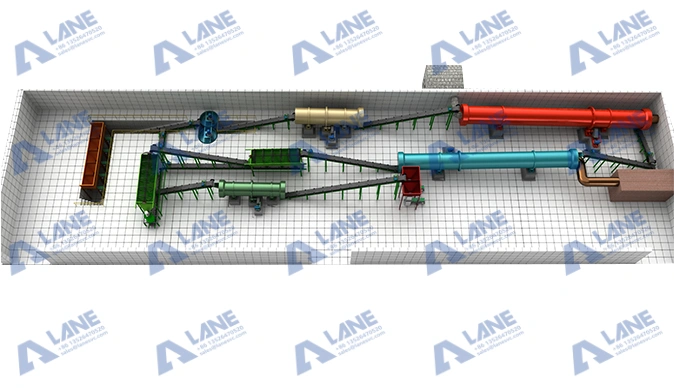

To successfully build an SSP fertilizer plant, a structured process flow with advanced equipment is required:

-

Rock Crushing: LANE’s high-capacity hammer crushers or roll crushers reduce phosphate rock to an optimal particle size for acid reaction. Typical crusher capacity ranges from 10–50 t/h, with adjustable gap settings for precise particle control.

-

Mixing & Acidulation: Precision paddle mixers and acidulation reactors ensure complete chemical reaction. Inline pH sensors monitor slurry pH (target: 1.5–2.0), while temperature sensors maintain 60–65°C for optimal reaction kinetics.

-

Curing: LANE’s curing units control humidity (40–50%) and temperature to facilitate full conversion of phosphate rock to monocalcium phosphate. Curing time is typically 10–14 days in batch processes, or 4–6 days in continuous systems with rotating beds.

-

Granulation: Advanced rotary drum or disc granulators produce uniform granules (2–4 mm) with high mechanical strength (>95% intact granules) and low dust generation. Granulator rotation speed and feed moisture are adjustable for optimal granule growth.

-

Screening & Packaging: Vibrating screens classify granules by size, while automated bagging systems ensure accurate weight control (±0.5%). Oversized granules are recycled, and fine particles are returned to the granulator, maximizing yield.

Step 4: Choose the Right Equipment Supplier

To build an SSP fertilizer plant that ensures operational efficiency and high-quality output, selecting an experienced supplier is essential. LANE Heavy Industry provides:

-

High-efficiency crushers, mixers, granulators, and curing chambers engineered for continuous operation.

-

Automated process control systems with PLCs to monitor slurry pH, temperature, and flow rates in real time.

-

Energy-efficient designs reducing electricity consumption by 15–20% per ton of SSP produced.

-

On-site installation, commissioning, and training, minimizing downtime and ensuring operational readiness.

Rotary Drum Granulator

Step 5: Ensure Compliance and Safety

Environmental and worker safety is critical when you build an SSP fertilizer plant. LANE’s SSP lines include:

-

Dust extraction systems to capture fine phosphate particles, maintaining PM levels below 50 mg/m³.

-

Phosphogypsum management solutions, recycling up to 90% of byproducts.

-

Safety features like emergency stop circuits, temperature alarms, and acid handling automation to reduce workplace hazards

Step 6: Optimize for Local Market Needs – Indonesia Case Study

To effectively build an SSP fertilizer plant, it is essential to tailor production to local soil types, crop needs, and environmental conditions. For instance, our recent project with an Indonesian client demonstrates how LANE Heavy Industry applies customized solutions to meet regional agricultural requirements.

Indonesia’s soils are often acidic, which can reduce phosphorus availability to crops like rice, maize, and palm oil. To address this, LANE’s engineering team adjusted the P₂O₅ content in the SSP fertilizer to optimize nutrient uptake. Granule sizes were also fine-tuned, ranging from 2–4 mm, to ensure even soil distribution and better dissolution rates.

Furthermore, the curing process was customized based on local climate conditions. LANE installed curing units with humidity and temperature controls, allowing the reaction to fully convert phosphate rock into soluble phosphorus without compromising granule strength. The curing duration was carefully monitored using temperature sensors and moisture analyzers, ensuring optimal nutrient solubility for Indonesian crops.

Our team also designed a flexible plant layout to accommodate multiple product lines. This allows the client to produce different SSP blends for various regional crops, adjusting formulations as needed. With real-time monitoring of acidulation efficiency and granule quality, LANE’s equipment ensures consistent output that matches local soil chemistry and agricultural demands.

By combining advanced equipment, customized process parameters, and data-driven adjustments, LANE Heavy Industry’s approach exemplifies how an SSP production line can be tailored to local market needs, helping clients in Indonesia achieve higher yields, better fertilizer efficiency, and sustainable agricultural results.

Conclusion

Learning how to build an SSP fertilizer plant involves careful planning, the right technology, and an experienced partner. From initial design to equipment installation and operator training, LANE Heavy Industry ensures every stage of your SSP plant project runs smoothly. If you are ready to build an SSP fertilizer plant that delivers high-quality fertilizer and strong market returns, contact LANE Heavy Industry today to start your journey.