SSP Fertilizer Made Easy: Advanced Batching Machines

- 2025-08-16

SSP Fertilizer Made Easy: Advanced Batching Machines

The global demand for high-quality fertilizers continues to rise as agriculture expands to meet the needs of a growing population. Among all phosphorus fertilizers, Single Super Phosphate (SSP) remains a cost-effective and widely used option that improves crop yields and soil fertility. A key component in ensuring high efficiency and consistent quality in SSP production is the use of Advanced Batching Machines. These machines play a critical role in modern SSP fertilizer production lines, guaranteeing precise material handling and continuous operation.

1. Introduction to Batching Machines

Batching machines, also known as distribution or silo allocation devices, are essential equipment in an SSP production line. They are responsible for delivering raw materials or intermediate products to different stages of production in pre-determined proportions and quantities. Typically installed between storage silos and key equipment like mixers, granulators, or dryers, Advanced Batching Machines ensure uniform material distribution and steady feed, which is vital for producing high-quality SSP fertilizer.

LANE company, we provide state-of-the-art Advanced Batching Machines that seamlessly integrate into SSP production lines. Our machines are designed to handle large-scale production while maintaining precise control over material flow, making them ideal for both new plants and facility upgrades.

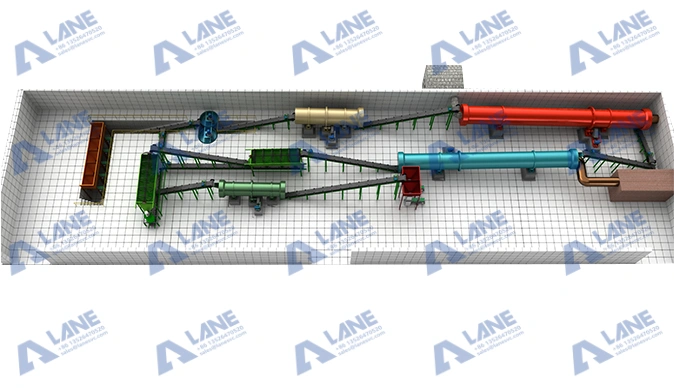

LANE’ batching machine

2. Key Functions of Batching Machines

(1) Uniform Material Distribution

In SSP production, phosphate rock, sulfuric acid, and other raw materials must be blended in specific ratios. Advanced Batching Machines distribute materials evenly to mixers or granulators, preventing uneven stacking that could compromise the uniformity of the mixture. This ensures consistent fertilizer quality, which is critical for customer satisfaction and crop performance.

(2) Continuous Production Line Operation

SSP production requires uninterrupted material supply to granulation, drying, and packaging processes. Advanced Batching Machines maintain a stable flow rate, preventing equipment downtime due to material shortages. This feature significantly improves the overall efficiency and output of the SSP production line.

(3) Optimized Process Control

Different SSP batches may require variations in formulation. With Advanced Batching Machines, operators can adjust the feed rate and distribution ratio according to production requirements. This flexibility allows for precise process control and ensures consistency across multiple production cycles.

(4) Reduced Equipment Wear

By distributing materials evenly, Advanced Batching Machines prevent local overloads that can damage downstream equipment such as mixers and granulators. This not only prolongs the lifespan of the machinery but also reduces maintenance costs and operational interruptions.

3. Working Principles of Batching Machines

Advanced Batching Machines typically operate using one of the following methods:

-

Screw Batching: Material is transported through a screw conveyor and evenly distributed to multiple outlets. Suitable for powders or granules.

-

Bucket Wheel Batching: A bucket wheel lifts and distributes material to several outlets, ideal for granular or blocky raw materials.

-

Electronic Quantitative Batching: Combining weighing and control systems, this method ensures precise material distribution by weight or volume, perfect for large-scale SSP production.

Our company’s Advanced Batching Machines are designed with all three methods in mind, offering customizable options to match different production requirements.

4. Placement in the SSP Production Line

In a typical SSP fertilizer production line, Advanced Batching Machines are strategically positioned:

-

Between raw material silos and mixers: To control the amount of phosphate rock, limestone, and other inputs.

-

Between mixers and granulators: To ensure a steady, uniform flow of blended materials for granulation, improving pellet quality.

-

Before dryers or packaging units: To supply semi-finished or finished products at a consistent pace, ensuring smooth operation of subsequent processes.

By incorporating our Advanced Batching Machines, your SSP production line can achieve higher productivity, reduced downtime, and improved fertilizer quality.

5. Advantages of Advanced Batching Machines

-

Enhance production efficiency and ensure continuous operation.

-

Precisely control material ratios to maintain consistent fertilizer quality.

-

Minimize equipment wear, lowering maintenance costs.

-

Flexible and adjustable to meet different batch formulations.

-

Fully compatible with automation systems, enabling smart and efficient SSP production.

Our company offers complete turnkey solutions for SSP fertilizer plants. From supplying Advanced Batching Machines to designing high-efficiency SSP production lines, we provide everything needed to establish a modern, reliable, and environmentally friendly fertilizer facility.

Conclusion

In SSP fertilizer production, Advanced Batching Machines are crucial for connecting raw material storage with production processes. They ensure uniform material distribution, continuous supply, and efficient operation, directly contributing to higher output and product quality. Choosing the right batching machine and production line design is essential for modern SSP factories aiming for maximum efficiency and sustainability.

Contact us today to learn how LANE’S Advanced Batching Machines and turnkey SSP production line solutions can help you build a high-performance fertilizer plant and achieve long-term success in the industry.